Introduction

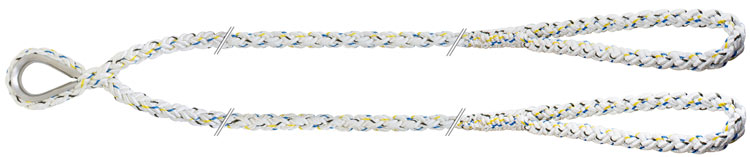

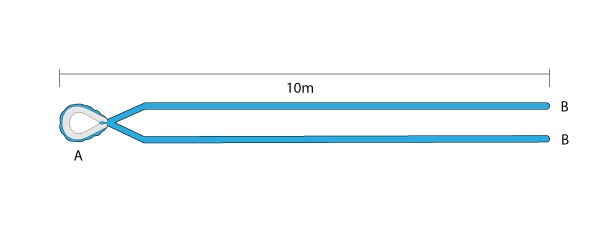

When securing a yacht to a single mooring buoy, boat owners commonly choose either a single rope strop or a V-bridle configuration.

Each set-up has its advantages: the Single Strop offers simplicity and fewer connection points, while a V-bridle can distribute the load across multiple deck fittings, reducing interference around bow fittings such as the forestay, furler, bow roller, anchor and windlass.

To provide clear, evidence-based guidance, we carried out a two-stage break-testing programme comparing both configurations using 14 mm LIROS Anchorplait Nylon.

Test Objective

- Compare the breaking load of a single strop versus V-bridle and Y-bridle configurations

- Assess the impact of asymmetric loading (one leg carrying more strain)

- Examine how eye and centre splices perform under real-world mooring conditions

Why Two Stages?

The testing followed a two-stage path for practical and logistical reasons.

During a factory visit to LIROS in Germany, Jimmy Green brought pre-spliced assemblies from the UK to perform initial break tests.

However, the LIROS test bed requires a 10 metre tail to be wrapped around a drum before clamping to prevent premature failure due to clamp compression.

This set-up limited space for multiple tails, preventing us from testing the equal-load V-bridle configuration.

The visit itinerary also meant there was no opportunity to evolve the testing method on the day.

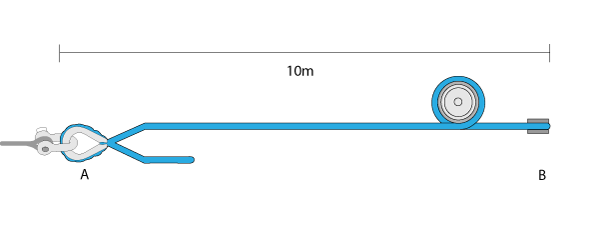

Once back in the UK, we had time to develop a loop-splice and shackle arrangement that removed the drum constraint.

Although the LIROS bed could have accommodated this new method, it proved more economical and practical to complete the testing at the Marlow Ropes facility in Hailsham.

Stage 1 – Initial Testing at LIROS (Germany)

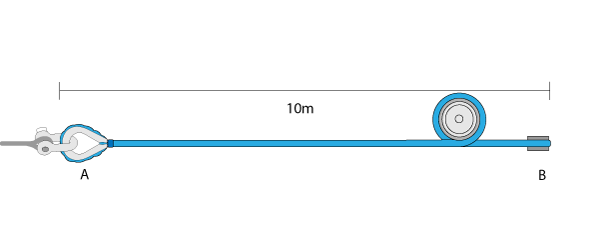

Test Set-up

- Rope: 14 mm Anchorplait Nylon

- Bed: LIROS in-house test rig

- Method: 10 m tail wrapped around test drum before clamping

- Limitation: Could not accommodate dual tails for equal-load V-bridle

Configurations & Results

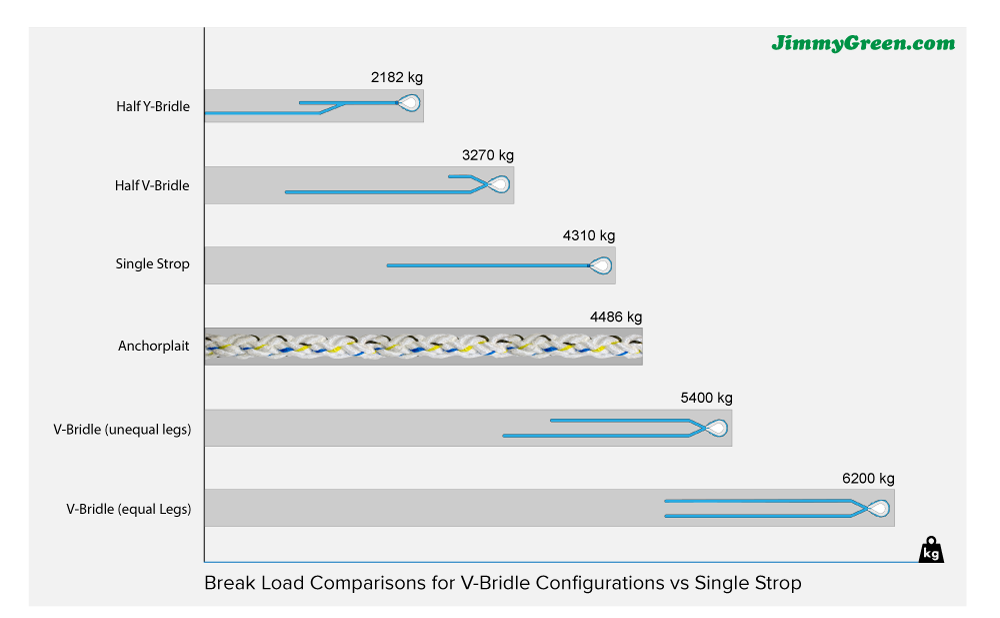

| Test No. | Configuration | Description | Break Load (kg) | Remarks | % of Linear BL KG |

| 1 | Single Strop | 10m strop with stainless steel thimble | 4310 | Baseline single strop strength | 96% |

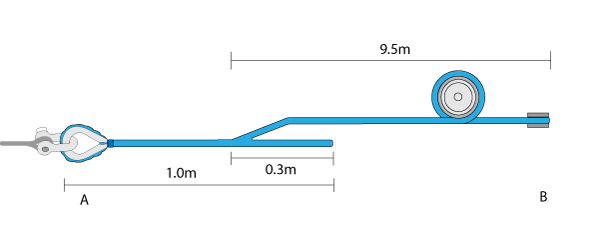

| 2 | Half Y-Bridle | 1m eye + 9.5m leg spliced into side; load on one leg | 2182 | Shows weakness under asymmetric loading | 48% |

| 3 | V-Bridle (equal load) | Centre eye splice with two 10m legs | – | Not possible due to drum space requirement | N/A |

| 4 | Half V-Bridle | Centre eye splice with 10m + 0.3m legs; load on one side | 3270 | Centre splice behaviour under one-leg load | 73% |

Linear Break load of LIROS Anchorplait Nylon = 4486kg

Stage 2 – Refined Testing at Marlow (UK)

To capture the missing data, the team refined the setup so that each rope end was spliced into a loop and shackled directly to the test bed, removing the need for long tails.

This loop-and-shackle system allowed a direct, symmetrical pull across the V-bridle’s centre eye and provided the flexibility to simulate unequal leg lengths to mirror a yacht lying slightly off-centre on its mooring.

Configurations and Results

| Test No. | Configuration | Break Load (kg) | Remarks | % of Linear BL KG |

| 1 | Centre eye splice with two equal 10m legs; equal load shared | 6200 | Replicates ideal straight pull | 138% |

| 2 | One leg 10cm shorter; simulates boat lying to one side | 5400 | Demonstrates strength reduction from imbalance | 120% |

Linear Break load of LIROS Anchorplait Nylon = 4486kg

Comparison Chart for V-Bridle Configurations vs Single Strop

Discussion

- The single strop provides a strong and straightforward solution but cannot share load between two bow points.

- The half Y-bridles and half V-bridles confirm predictable reductions in capacity when only one leg carries the load or when geometry distorts the splice

- The half Y-bridle showed a reduced loaded bearing capacity compared to the half V-bridle

- The equal-leg V-bridle recorded the highest overall strength (~6.2 t), confirming that balanced load-sharing offers both superior performance and lower stress on individual components

- A modest leg-length difference (10 cm) reduced capacity by ~13%, underlining the benefit of matching leg lengths in service

Conclusion

Early results clearly indicate that a well-matched V-bridle offers excellent total strength and practical mooring advantages. Unequal leg geometry introduces some loss, but the configuration remains robust and secure. For the purposes of permanent mooring buoys, the same diameter line for both a single strop and V-bridle solution is the logical deduction. This provides a suitable safety allowance for the variable break strain experienced during unequal loading of the legs.

The comparative strength loss of the Y-half compared to the V-half indicates that a centre eye splice is preferable for bridle-designed permanent mooring strops. Jimmy Green Marine offers a joining splice for applications that require a Y configuration.

Further testing of the Y-half splice with variable loadings is required to determine the optimal load distribution that ensures the joining splice is secure.

Acknowledgements

Stage 1 testing conducted at LIROS GmbH, Germany, during a Jimmy Green Marine factory visit.

Stage 2 testing performed at Marlow Ropes Ltd, UK.

Assemblies supplied by Jimmy Green Marine, Beer, East Devon.